Getting Started: Smart Card Demo

Configuration

3: Low Pin Count USB Development Kit

Configuration

4: PICDEM FS USB

Configuration

3: PIC18F14K50 + LPC Board

Configuration

4: PICDEM FS USB

Required Hardware:

To run this project, you will need one of the

following sets of hardware:

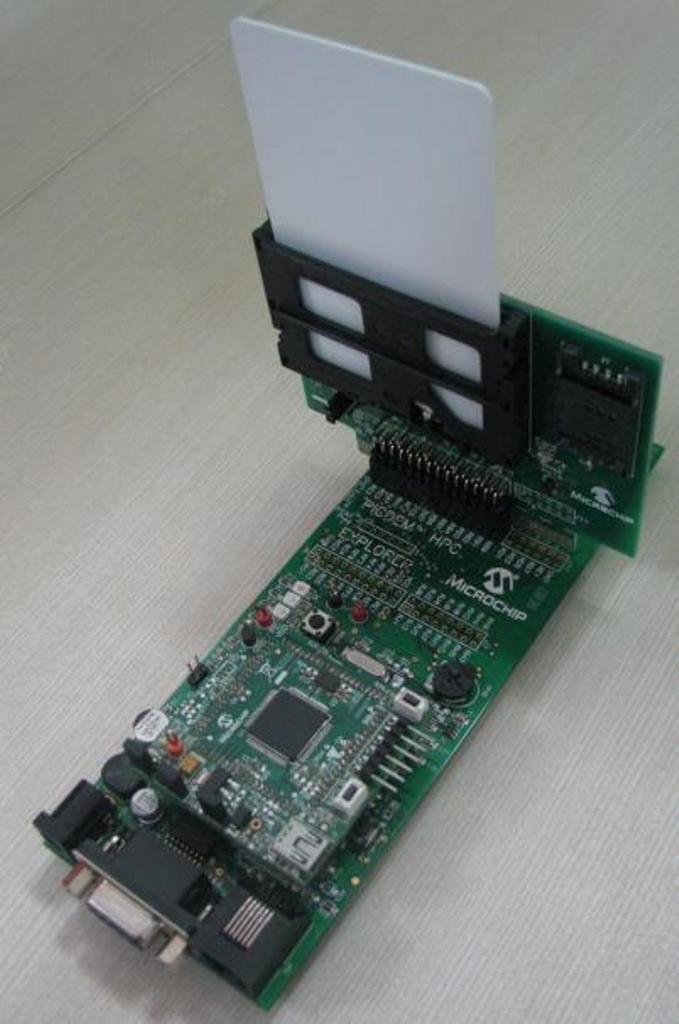

Configuration 1: HPC Explorer

High

pin count (HPC) Explorer (DM183022)

SC (Smart/Sim Card) PICTail Board

And

one of the following PIMs

PIC18F87J50

Plug-In-Module (PIM) (MA180021)

PIC18F46J50

Full Speed USB Demo Board (MA180024)

Configuration 2: Explorer 16

Explorer

16 (DM240001)

SC

(Smart/Sim Card) PICTail Board

And one of the following PIMs

PIC24FJ256GB110 Plug-In-Module (PIM) (MA240014),

PIC32MX795F512L Plug-In-Module (PIM) (MA320003),

dsPIC33FJ128MC710,

PIC24HJ256GP610

Configuration 3: Low Pin Count USB Development Kit

Low Pin Count USB Development Kit with PICKit 2

Debugger/Programmer (DV164126)

or without

Debugger/Programmer (DM164127).

SC (Smart/Sim Card) PICTail Board

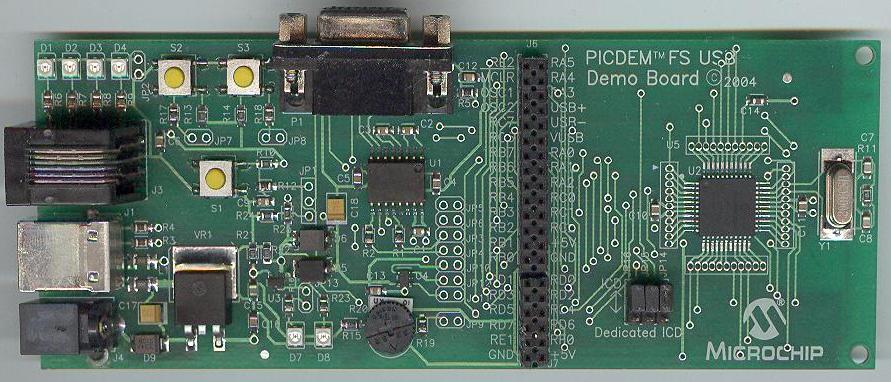

Configuration 4: PICDEM FS USB

PICDEM

FS USB (DM163025)

SC (Smart/Sim Card) PICTail Board

Configuring the Hardware:

This

section describes how to set up the various configurations of hardware to run

this demo.

Configuration 3: PIC18F14K50 + LPC Board

Configuration 4: PICDEM FS USB Board

Configuration 1: HPC Explorer

1)

Before inserting PIC18F87J50 PIM or PIC18F46J50 PIM in the HPC Explorer board,

insure that the processor selector switch (S3) is in the “ICE” position as seen

in the image below. Failure to so will

result in difficulties in getting the PIC18F87J50/PIC18F46J50 PIM to sit

properly on the HPC Explorer.

2)

Before inserting PIC18F87J50/PIC18F46J50 PIM into the HPC Explorer board,

remove all the attached cables from both the boards. Be careful while inserting

the PIM into HPC board. Insure that no pins are bent or damaged during the process. Also insure that the PIM is not shifted in

any direction and that all of the headers are properly aligned.

3) Insert the J4 port pins of SC (Smart/Sim

Card) PICTail Board in the J3

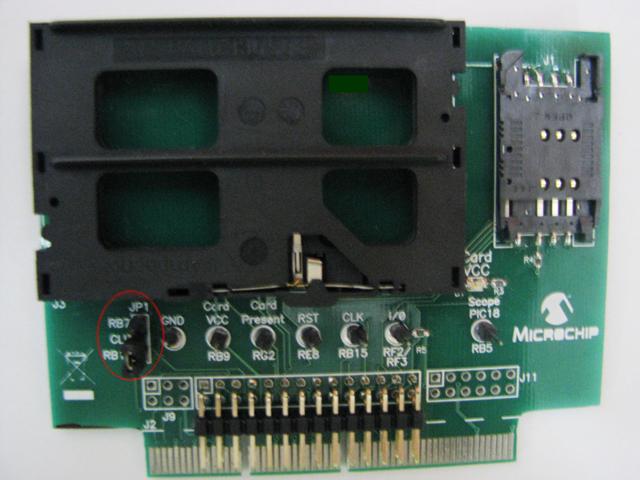

Configuration 2: Explorer 16

1)

Before attaching the PIM to the Explorer 16 board, insure that the processor

selector switch (S2) is in the “PIM” position as seen in the image below.

2)

Short the J7 jumper to the “PIC24” setting

3)

Be careful while inserting the PIC24FJ256GB110 PIM or any other appropriate PIM

into Exp 16 board. Insure that no pins are bent or damaged during the

process. Also insure that the PIM is not

shifted in any direction and that all of the headers are properly aligned.

4)

Short JP1 to SRC1 (i.e. RD1) or SRC2 (i.e. RB15) based upon the smart card

clock pin configured in the firmware: Example: - Short JP1 to SRC1 while using

PIC24FJ256GB110 demo and Short JP2 to SRC2 while using PIC32MX795F512L demo.

5) Insert the J2 slot of SC (Smart/Sim Card) PICTail

card into J5

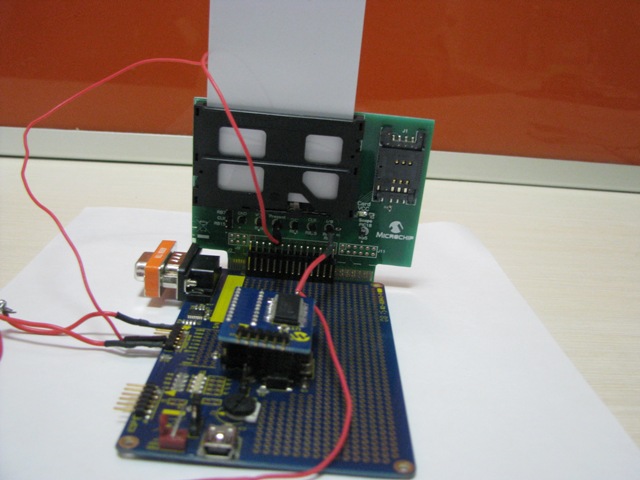

Configuration 3: PIC18F14K50 + LPC Board

1)

Make sure that JP1 of SC PICTail card is left open. Make sure that J12 of LPC

board is left open. One side of J4 port pins of the SC (Smart/Sim Card) PICTail

Board matches with the J11

1) Short Tx & Rx line of the

UART (i.e. short pin 1 & pin 6 of J13 port using a wire in the LPC board) and

connect it to I/O pin of SC PICTail board.

2) Connect RB6 (i.e. pin 5 of J13

port in LPC board) to “Card Present” signal pin of SC PICTail board as shown

below.

Configuration 4: PICDEM FS USB

1) If using the PICDEM FS USB Demo Board, no hardware

related configuration or jumper setting changes should be necessary. The demo board need only be programmed with

appropriate firmware.

2) Don’t short the jumper at J11 port.

3) Insert the J2

To

run this project, you will need to load the corresponding firmware into the

devices.

The

source code for this demo is available in the “<Install Directory\Smart Card

Demo” directory. In this directory you

will find all of the user level source and header files, linker file as well as

project file for each of the hardware platforms. Find the project (*.mcp) file that

corresponds to the hardware platform you wish to test. Compile and program the

demo code into the hardware platform. For more help on how to compile and

program projects, please refer to the MPLAB® IDE help available through the

help menu of MPLAB (Help->Topics…->MPLAB IDE).

This demo uses the selected hardware platform as a Smart

card reader. The demo has to be run in the debug mode of MPLAB IDE. Please

refer “Configuring the Hardware” section for the bench setup connections.

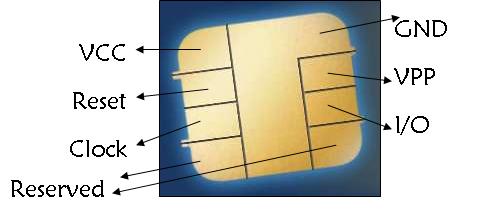

Smart Card consists of 8 pins namely:-

I/O: Input or Output for serial data to the integrated circuit inside the card.VPP: Programming voltage input (optional use by the card).GND: Ground (reference voltage).CLK: Clocking or timing signal.RST: Reset Signal to the Card.

VCC: Power supply input (optional use by the card).

Communication between the interfacing device and smart card

is done as per the following steps:-

·

Insertion

of the smart card in the slot.

·

Detection

of the smart card insertion by the microcontroller (interfacing device).

·

Microcontroller

does the cold reset of the smart card.

·

Answer

to Reset (ATR) response by the card.

·

PPS

exchange (if smart card supports it).

·

Execution

of the transaction(s) between the card & the interfacing device.

·

Removal

of the smart card from the slot.

·

Detection

of the smart card removal by the microcontroller.

·

Deactivation

of the contacts.

At the current times there are two communication protocols

that are in general use:-

·

T

= 0 asynchronous half duplex character transmission.

·

T

= 1 asynchronous half duplex block transmission.

The data transfers between the card and the terminal happens

on the single wire I/O line. The smart card library supports both T=0 & T=1

protocol.

Example code for T=0 cards:-

The demo executes the card commands namely SUBMIT CODE,

SELECT FILE, READ RECORD & WRITE RECORD. The command list can be extended further

as per the project requirement.

Example code for T=1 cards:-

The demo executes the "Get CPLC (Card Production Life

Cycle) data" command for T=1 java card. The command list can be extended

further as per the smart card manual and the project requirement.

The demo uses the signal connections between the smart card

& PIC micro port pins as per the below table:-

|

Signal Name |

PIC18F46J50 |

PIC18F87J50 |

PIC18F4550 |

PIC18F14K50 |

|

SIM_CARD_DET |

RB1 |

RB1 |

RB1 |

RB4 |

|

SMART_CLK |

RB2 |

RC2 |

RC2 |

RC2 |

|

SMART_I/O |

RC6,RC7 |

RC6,RC7 |

RC6,RC7 |

RB7,RB5 |

|

SMART_RST |

RB4 |

RB4 |

RB4 |

RC1 |

|

SMART_CARD_DET |

RB3 |

RB3 |

RB3 |

RB6 |

|

SMART_VCC |

RB0 |

RB0 |

RB0 |

RC0 |

|

Signal Name |

PIC24FJ256GB110 |

PIC32MX795F512L |

dsPIC33FJ128MC710 |

PIC24HJ256GP610 |

|

SIM_CARD_DET |

RB1 |

RB1 |

RB1 |

RB1 |

|

SMART_CLK |

RB15 |

RD1 |

RD1 |

RD1 |

|

SMART_I/O |

RC4, RF2 |

RF2 , RF8 |

RF2 , RF3 |

RF2 , RF3 |

|

SMART_RST |

RE8 |

RE8 |

RE8 |

RA12 |

|

SMART_CARD_DET |

RB0 |

RB0 |

RB0 |

RB0 |

|

SMART_VCC |

RB9 |

RB9 |

RB9 |

RB9 |

“SMART_CARD_DET”/”SIM_CARD_DET” signals indicate the

presence of Smart Card/Sim Card to the microcontroller. Either of one between

Smart Card & Sim Card has to be inserted in the Smart Card PICTail board.

If both the cards are inserted at a time in the PICTail card, then the demo

won’t work successfully.

If the user wants to connect the smart card signals to

different port pins of the micro, then he or she needs to modify the pin

mapping in “sc_config.h” file.

The demo

waits in the while(1) loop until the smart card is inserted in the smart card

connector slot. Once the card is inserted in the slot, ATR (Answer to Reset)

and PPS (Protocol & Parameter Selection) operations are performed. Then

after the execution of card commands is done as per the smart card manual

provided by the manufacturer. If the user inserts T=0 card in the slot, then

“SC_TransactT0” function is called & the result of the executed command

from the smart card is stored in “apduData”. If the user inserts T=1 card in

the slot, then “SC_TransactT1” function is called & the result of the

executed command from the smart card is stored in “apduData”. Variable

“cardResponse” stores the status codes & the length of the received data

from the smart card.

Note:

After initially being reset by the card reader, the smart card responds with a

string of characters known as the Answer to Reset, or ATR. These characters

consist of an initial character, TS, followed by a maximum of 32 additional

characters. Together, these characters provide information to the card reader

about how to communicate with the card for the remainder of the session. If the

card reader wants to modify any of these data transmission parameters in the

smart card, then it must perform PPS in accordance with ISO/IEC 7816-3 before

the transmission protocol is actually used.

For more

details about smart card communication using PIC microcontrollers, please refer

the application note AN1370

Troubleshooting Tips:

Issue

1: How to get the exact delays for Work Wait time functionality?

Solution: It is advisable to use Timers to generate the exact delays.

Trademarks:

The Microchip name and logo, the Microchip logo,

MPLAB, and PIC are registered trademarks of Microchip Technology Incorporated

in the

PICDEM and PICTail are trademarks of Microchip

Technology Incorporated in the

Microsoft, Windows, and Windows Vista are either

registered trademarks or trademarks of Microsoft Corporation in the

SD is a trademark of the SD Association in the

U.S.A and other countries

.JPG)

.JPG)

.JPG)