Easy Driver Examples

Easy Driver Examples

Sample code and

projects to get your stepper running!

Description:

Lots of folks buy EasyDrivers or BigEasyDrivers and then

get them to work just fine in their project. But some don't, and so

I thought it would be a good idea to write down some simple

instructions for getting your Easy Driver working as quickly and

easily as possible.

All of these examples are going to be done with my Easy Driver and

Big Easy Driver stepper motor driver boards driving several

different random stepper motors I have lying around the lab. I will

be generating the step and direction pulses with an Arduino UNO and a chipKIT

UNO32, although all of these examples should work with any

Arduino or Arduino clone or Arduino compatible (like all chipKIT

boards).

And don't forget to read Dan Thompson's excellent Easy

Driver tutorial blog post if you want to read more up on this

stuff. Some great questions answered in the comments on that blog

post.

Note1: All examples will work equally well with Easy Drivers or Big

Easy Drivers.

Note2: All examples will work on Arduino as well as chipKIT boards

(and some will run much better on chipKIT because of the PIC32

speed)

Note3: All examples show a barrel jack for power input - you need to

supply power to the EasyDrivers somehow, but it doesn't need to be a

barrel jack. You should have a power supply that can output some

voltage between 5V and 30V, at 1 Amp or more.

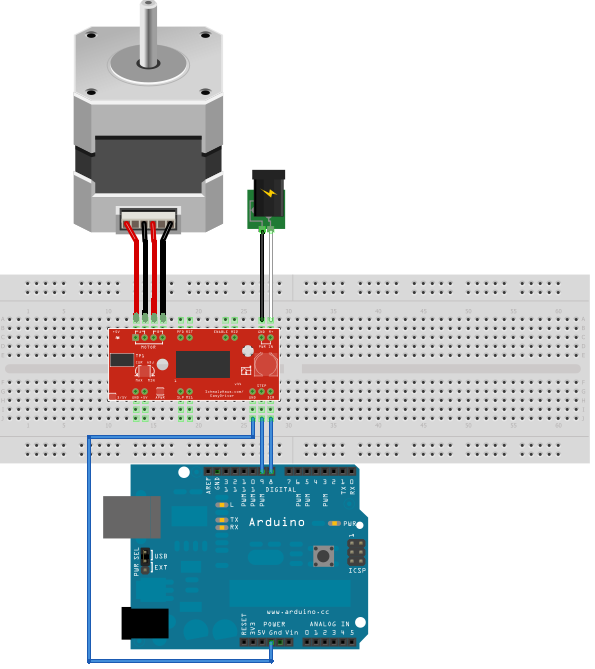

Example 1: Basic Arduino setup

This is the most basic example you can have with an Arduino, an Easy

Driver, and a stepper motor. Connect the motor's four wires to the

Easy Driver (note the proper coil connections), connect a power

supply of 12V is to the Power In pins, and connect the Arduino's

GND, pin 8 and pin 9 to the Easy Driver.

Then load this sketch and run it on your Arduino or chipKIT:

void setup()

{

pinMode(8, OUTPUT);

pinMode(9, OUTPUT);

digitalWrite(8, LOW);

digitalWrite(9, LOW);

}

void loop() {

digitalWrite(9, HIGH);

delay(1);

digitalWrite(9, LOW);

delay(1);

}

It doesn't get much simpler than that. What is the code doing? It

sets up pin 8 and 9 as outputs. It sets them both low to begin with.

Then in the main loop, it simply toggles pin 9 high and low, waiting

1ms between toggles. We use pin 9 as the STEP control and pin 8 as

the DIRECTION control to the Easy Driver.

Since we are not pulling either MS1 or MS2 low on the Easy Driver

low, the Easy Driver will default to 1/8th microstep mode. That

means that each time the "digitalWrite(9, HIGH);" call is executed,

the stepper motor will move 1/8th of a full step. So if your motor

is 1.8 degrees per step, there will be 200 full steps per

revolution, or 1600 microsteps per revolution.

So how fast is this code going to run the stepper? Well, with the

STEP signal 1ms high and 1ms low, each complete pulse will take 2ms

of time. Since there are 1000ms in 1 second, then 1000/2 = 500

microsteps/second.

What if we wanted the motor to go slower? We change the delay();

lines to have longer delays. If you use delay(10); for both, the

you'll move at 50 microsteps/second.

What if you wanted the motor to go faster? We can't really delay for

less than 1 ms, can we? Yes, of course we can! We can change the

delay() calls to delayMicroseconds(100); calls and then each delay

would be 100 microseconds (or us), so the motor would be driven at

5000 microsteps/second.

Now, one thing you should play with is the current adjustment pot on

your Easy Driver. You need a tiny little screw driver to turn it,

and be sure not to force it too far one way or the other (they're

delicate). Also, some Easy Drivers were built with pots that have no

physical stops on them, so they spin around and around. As you run

the above code, slowly turn the pot one way or the other. Depending

upon the type of motor you have (and its coil resistance) you may

hear/feel no difference as you spin the pot, or you may notice quite

a big difference.

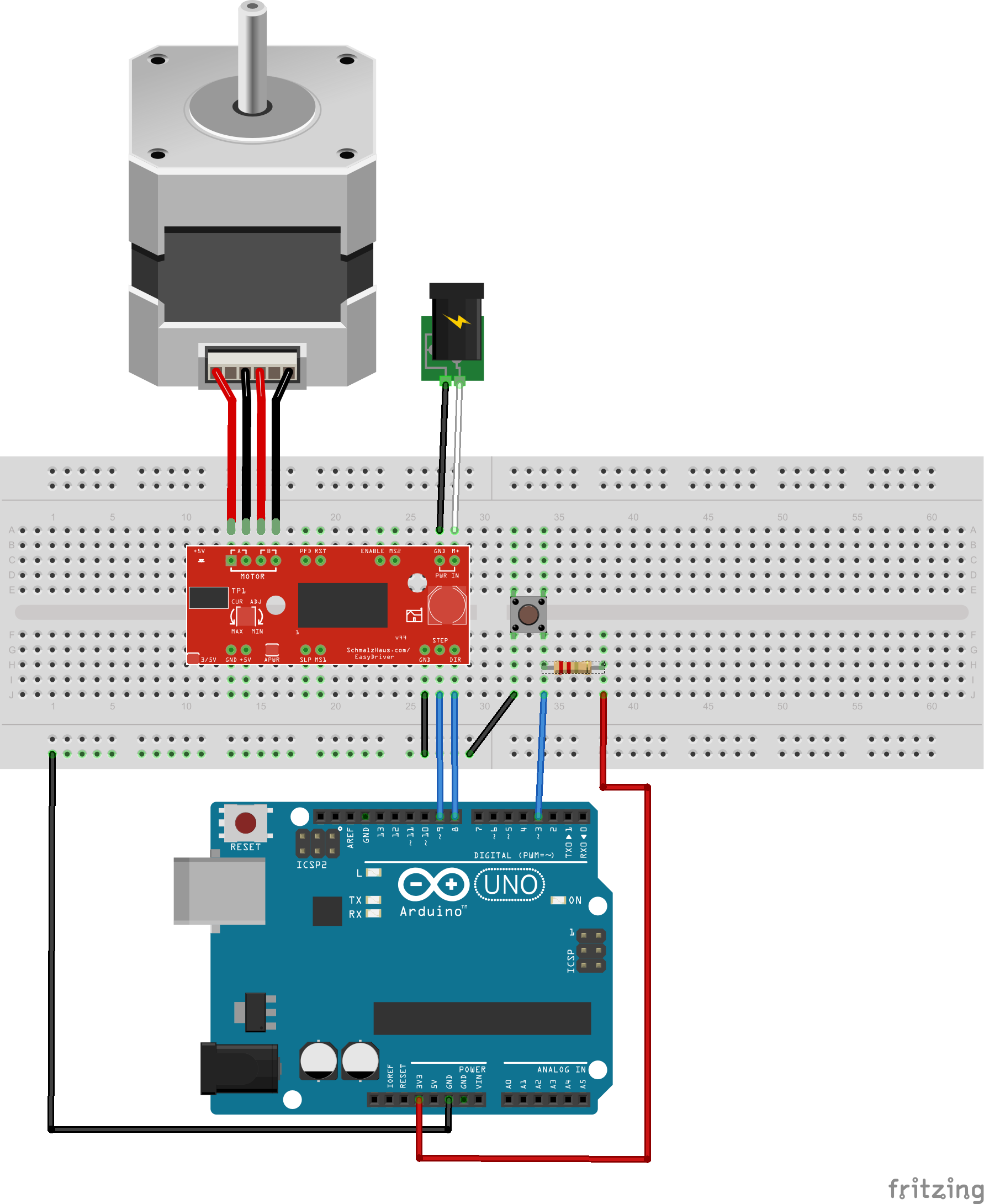

Example 1.5: Moving when a button is pressed

This example is almost exactly the same as Example 1, but we've

added a button. When the sketch is running, it waits for a button

press (a LOW on Arduino pin 3) and then it starts to rotate the

stepper motor for 3200 steps. It is written in such a way as to be

'non-blocking', which means you can easily add other things into the

loop() function without having to stop those things in order to run

the stepper motor. (Much like the way AccelStepper does it below.)

We added a push button switch between Pin 3 and ground, and then

used a 3.3K pull up resistor on pin 3 to 3.3V.

#define DISTANCE 3200

int StepCounter = 0;

int Stepping = false;

void setup()

{

pinMode(8, OUTPUT);

pinMode(9, OUTPUT);

digitalWrite(8, LOW);

digitalWrite(9, LOW);

pinMode(3,INPUT);

}

void loop() {

if (digitalRead(3) == LOW && Stepping ==

false)

{

Stepping = true;

}

if (Stepping == true)

{

digitalWrite(9, HIGH);

delay(1);

digitalWrite(9, LOW);

delay(1);

StepCounter = StepCounter + 1;

if (StepCounter == DISTANCE)

{

StepCounter = 0;

Stepping = false;

}

}

}

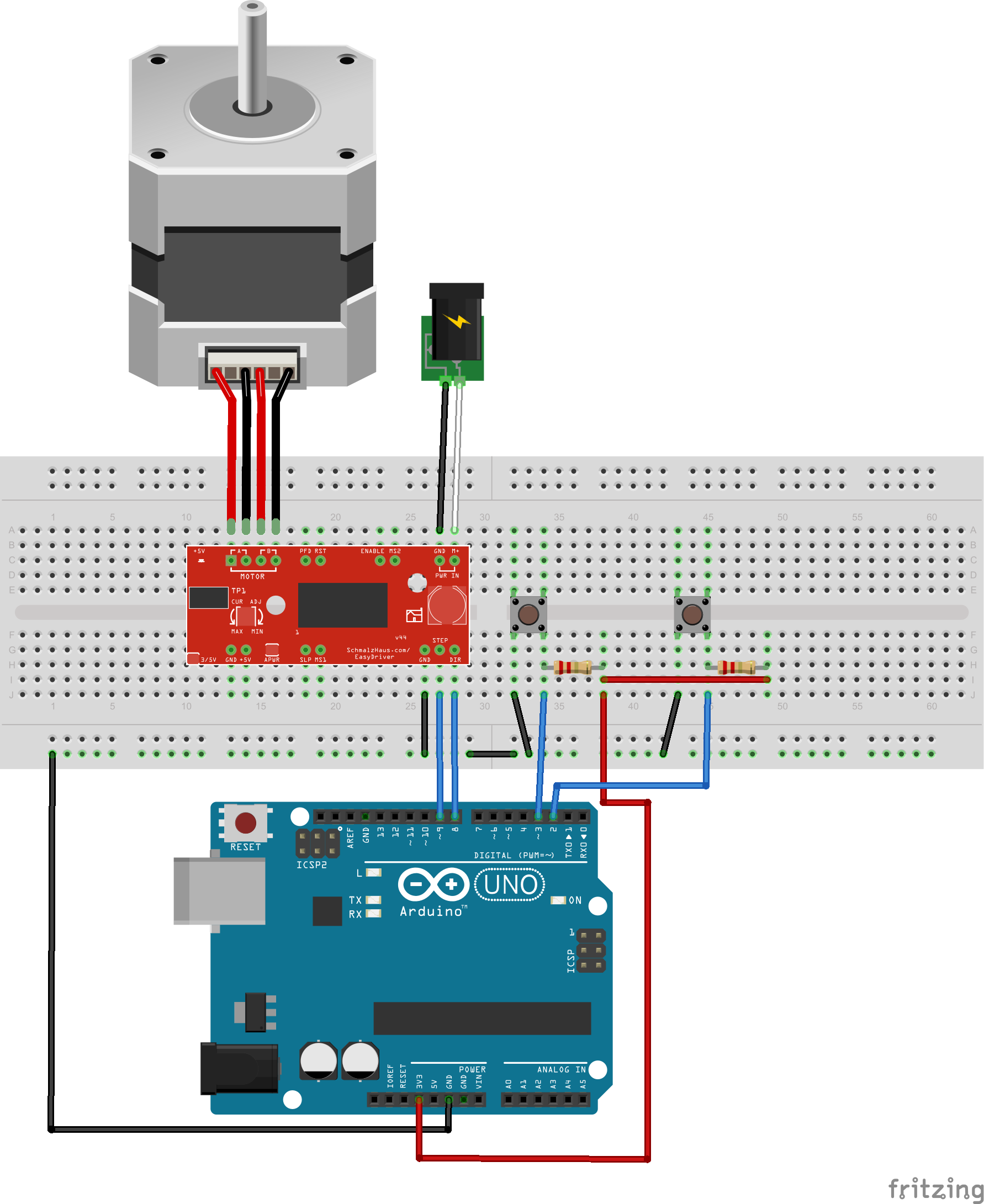

Example 1.6 : Using two buttons to move forward and reverse

This example is almost exactly like 1.5, except that we've added a

second button on Arduino Pin 2, again with a pull up resistor to

3.3V. When you press one button, the motor will move 3200 steps in

one direction, and when you press the other button, it will move

3200 steps in the other direction.

#define DISTANCE 3200

int StepCounter = 0;

int Stepping = false;

void setup() {

pinMode(8, OUTPUT);

pinMode(9, OUTPUT);

digitalWrite(8, LOW);

digitalWrite(9, LOW);

pinMode(2, INPUT);

pinMode(3, INPUT);

}

void loop() {

if (digitalRead(3) == LOW && Stepping ==

false)

{

digitalWrite(8, LOW);

Stepping = true;

}

if (digitalRead(2) == LOW && Stepping ==

false)

{

digitalWrite(8, HIGH);

Stepping = true;

}

if (Stepping == true)

{

digitalWrite(9, HIGH);

delay(1);

digitalWrite(9, LOW);

delay(1);

StepCounter = StepCounter + 1;

if (StepCounter == DISTANCE)

{

StepCounter = 0;

Stepping = false;

}

}

} Example 1.7: Moving when a switch is pressed at a very specific

speed

This example is exactly like 1.5 in setup, but allows you to

specify the exact RPM of the motor. It will spin the motor at that

speed as long as the button is held down.

/* This example assumes a step/direction driver with Step on pin

9, Direction on pin 8

* And an input switch on pin 3. The switch is a

switch to ground, with pin 3 pulled

* high with a pullup resistor. When the switch is

turned on (closed, i.e. goes low)

* the the sepper motor steps at the rate specified

(104 RPM in this code, with

* 1/8th microstepping of a 200 steps/rev motor)

*/

#define

RPMS

104.0

#define

STEP_PIN

9

#define

DIRECTION_PIN

8

#define

GO_PIN

3

#define

STEPS_PER_REV 200

#define MICROSTEPS_PER_STEP 8

#define MICROSECONDS_PER_MICROSTEP

(1000000/(STEPS_PER_REV * MICROSTEPS_PER_STEP)/(RPMS / 60))

uint32_t LastStepTime = 0;

uint32_t CurrentTime = 0;

void setup()

{

pinMode(STEP_PIN, OUTPUT);

pinMode(DIRECTION_PIN, OUTPUT);

digitalWrite(STEP_PIN, LOW);

digitalWrite(DIRECTION_PIN, LOW);

pinMode(GO_PIN,INPUT);

}

void loop() {

if (digitalRead(GO_PIN) == LOW)

{

CurrentTime = micros();

if ((CurrentTime - LastStepTime) >

MICROSECONDS_PER_MICROSTEP)

{

LastStepTime = CurrentTime;

digitalWrite(STEP_PIN,

HIGH);

delayMicroseconds((MICROSECONDS_PER_MICROSTEP * 0.9)/2);

digitalWrite(STEP_PIN, LOW);

delayMicroseconds((MICROSECONDS_PER_MICROSTEP * 0.9)/2);

}

}

}

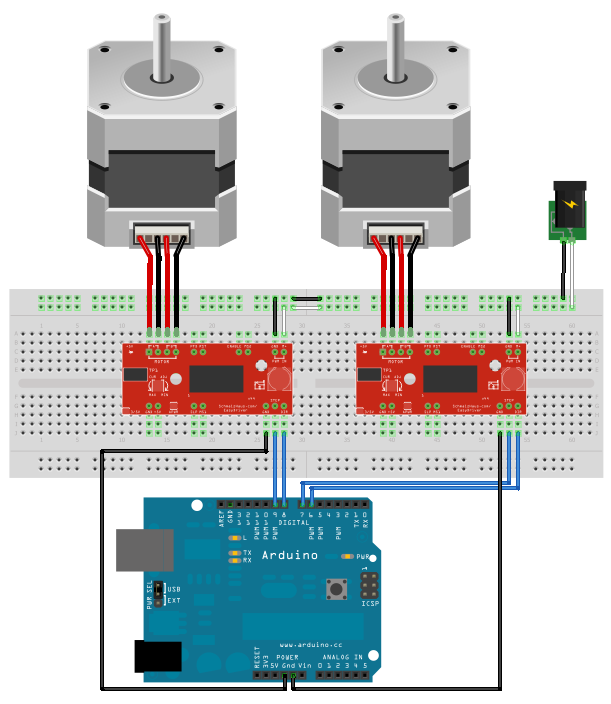

Example 1.8: Fine speed control of two motors with a joystick

This example was written by R. A. Stephenson and he kindly allowed us to

use it. He has a two axis joystick on two analog inputs, and two EasyDrivers

controlling two stepper motors. The analog inputs are sampled, and a non-blocking

recorded time method is used to determine when the step pulses should happen.

His code is nicely commented and shows that useful, real life projects can

be made without complicated libraries, but instead just by keeping careful

track of time. If you'd like to reach out to him with any questions, his

email address is theropod@yahoo.com

/*

Written by R. A. Stephenson for prototype Pan/Tilt Alt/Az small telescope or

binocular set pointer application.

Significant advice, and editorial guidance, supplied by Brian Schmalz

(designer of the Easy Driver® bipolar stepper motor driver board).

Test equipment:

Arduino® Nano, 2 - Easy Driver® bipolar stepper motor driver boards,

analog 2 axis joystick and salvage bipolar stepper motors,

which are both 1.8 degree per full step, being driven at 1/8 microstepping (Easy Driver default),

which equates to 200 full steps multiplied by 8 = 1600 pulses for one complete revolution of the motor

left right gearing provided by windshield wiper worm and wheel gears (ratio TBD)

up and down gearing provided by paper shredder square cut reduction set (ratio TBD)

project origin; July, 2018, this edit, Version 5.1, began Jan. 2019

last modified: Jan. 23, 2019

*/

//define Arduino pin assignments

//

#define step_pinx 2 // Arduino Digital output pin #2 is step signal pin for X axis L/R

#define dir_pinx 3 // Arduino Digital output pin #3 is direction control pin for X axis L/R

#define x_pin A0 // Arduino analog input from joystick for X axis L/R

#define y_pin A1 // Arduino analog input from joystick for Y axis U/D

#define step_piny 5 // Arduino Digital output pin #5 is step speed select signal pin for Y axis U/D

#define dir_piny 4 // Arduino Digital output pin #4 is direction control pin for Y axis U/D

//

//declare global variable

//

int xaxisState = LOW; //state of x axis stepper pulse set to ON

int yaxisState = LOW; //state of y axis stepper pulse set to ON

//

int XStepDelay;

int YStepDelay;

//

//

const long xhigh = 180; //interval to pulse X axis at slowest speed, change to fit application

const long xlow = 1; //interval to pulse X axis at highest speed, change to fit application

//

const long yhigh = 180; //interval to pulse Y axis at slowest speed, change to fit application

const long ylow = 2; //interval to pulse Y axis at highest speed, change to fit application

//

//

unsigned long previousMillisX = 0; //

unsigned long previousMillisY = 0; //

//

//

//

void setup() {

//

delay(1000); //1 second delay to allow easy drivers to power up

//

pinMode(dir_pinx, OUTPUT);

pinMode(step_pinx, OUTPUT);

pinMode(dir_piny, OUTPUT);

pinMode(step_piny, OUTPUT);

digitalWrite(step_pinx, xaxisState) ; //used in state machine switching for the stepper logic final drive (on or off setting)

digitalWrite(step_piny, yaxisState) ; //used in state machine switching for the stepper logic final drive (on or off setting)

//

}

//

void loop() {

//

unsigned long currentMillisX = millis(); //

unsigned long currentMillisY = millis(); //

//

//

int xValue = analogRead(A0); // x axis variable for joystick inputs controlling r/l PIN DEPENDENT!

int yValue = analogRead(A1); // y axis variable for joystick inputs controlling u/d PIN DEPENDENT!

//

//

if (xValue > 520) {

//if joystick moved RIGHT out of "null zone" to limit jitter

digitalWrite(dir_pinx, HIGH); // motor direction signal sent to Easy Driver X axis DIR pin (ON)

XStepDelay = map(xValue, 520, 1023, xhigh, xlow);

}

else if (xValue < 480) {

//if joystick moved LEFT out of null zone to limit jitter

digitalWrite(dir_pinx, LOW); // motor direction signal sent to Easy Driver X axis DIR pin (OFF)

XStepDelay = map(xValue, 0, 480, xlow, xhigh);

}

else if (yValue > 520) {

// if joystick moved DOWN out of null zone to limit jitter

digitalWrite(dir_piny, HIGH); //motor direction signal to Y axis Easy Driver DIR pin (ON)

YStepDelay = map(yValue, 530, 1023, yhigh, ylow); //

}

else if (yValue < 480) {

//if joystick moved UP out of null zone to limit jitter

digitalWrite(dir_piny, LOW); //motor direction signal to Y axis Easy Driver DIR pin (OFF)

YStepDelay = map(yValue, 0, 480, ylow, yhigh); //

} else {

digitalWrite(dir_piny, LOW); //motor direction signal to Y axis Easy Driver DIR pin (OFF)

digitalWrite(dir_pinx, LOW); // motor direction signal sent to Easy Driver X axis DIR pin (OFF)

// Setting LOW saves a bit of power

//could include signal to set Easy Driver(s) in "sleep" mode for geared drivetrains

}

//_____________

// If X axis (L/R) (Azimuth) motor needs to take a step, give it a step for the correct length of time,

//when that time has expired end the pulse signal

if ((xValue >= 520 || xValue <= 480) && ((unsigned long)(currentMillisX - previousMillisX) >= XStepDelay)) {

//if the joystick X axis values goes outside the null zone calculate

//how long it's been against those joystick values and control step pulse length

xaxisState = !xaxisState; // logic switch between states of step pulse pin on/off

digitalWrite (step_pinx, xaxisState); //control signal for step pin

//if the motor pulse is off, turn it on, and if the pulse is on, turn it off

previousMillisX = currentMillisX; //save the last x channel/axis pulse time on or off

}

else if (xValue <= 520 || xValue >= 480){ //if the joystick input isn't out of the null zone

digitalWrite(step_pinx, LOW); //turn off the step pulse

}

//________________

// If Y axis (U/D) (Altitude) motor needs to take a step, give it a step over the correct length of time,

//after that time has expired end the pulse signal

if ((yValue >= 520 || yValue <= 480) && ((unsigned long)(currentMillisY - previousMillisY) >= YStepDelay)){

//if the joystick Y axis values goes outside the null zone calculate

//how long it's been against those joystick values and control step pulse length

yaxisState = !yaxisState; // logic switch between states of step pulse pin on/off

digitalWrite (step_piny, yaxisState); //control signal for step pin

//if the motor pulse is off, turn it on, and if the pulse is on, turn it off

previousMillisY = currentMillisY; //save the last y channel/axis pulse time

}

else if (yValue <= 520 || yValue >= 480){ //if the joystick input isn't out of the null zone

digitalWrite(step_piny, LOW); //turn off the step pulse

//

//restart loop

}

}

Example 2: Moving back and forth

If we take Example 1, and simply change the sketch a little bit, we

can move a certain number of steps forward or backward. Like so:

int Distance = 0; // Record the number of steps we've

taken

void setup()

{

pinMode(8, OUTPUT);

pinMode(9, OUTPUT);

digitalWrite(8, LOW);

digitalWrite(9, LOW);

}

void loop() {

digitalWrite(9, HIGH);

delayMicroseconds(100);

digitalWrite(9, LOW);

delayMicroseconds(100);

Distance = Distance + 1; // record this

step

// Check to see if we are at the end of our move

if (Distance == 3600)

{

// We are! Reverse direction (invert

DIR signal)

if (digitalRead(8) == LOW)

{

digitalWrite(8, HIGH);

}

else

{

digitalWrite(8, LOW);

}

// Reset our distance back to zero

since we're

// starting a new move

Distance = 0;

// Now pause for half a second

delay(500);

}

}

Now using this sketch, we move for 3600 steps in one direction,

pause for a bit, and move 3600 steps in the other direction. I'm

sure you can figure out how to make many different lengths of moves

now. And you can change the delay between steps for each move to

occur at separate speeds.

Note that, just like example 1, each 'step' from the code's

perspective is 1/8th of the motor's full step, because we are

assuming the use of the EasyDriver in 1/8th microstep mode. If you

use the Big Easy Driver, it's default is 1/16 microstep, so adjust

your expectations for motor motion accordingly.

Example 3: Using a pre-built library - AccelStepper

One thing the above examples can't do well is handle multiple

steppers from the same Arduino or chipKIT. Also, acceleration and

deceleration are difficult as well. Other people have run into this

problem, and so now we have libraries that we can download and

install into the Arduino IDE or MPIDE to fix these problems.

Download the zip file for the AccelStepper library from this

page. Unzip the downloaded file, and place the AccelStepper in

to the libraries folder in your Arduino install directory. Note that

for MPIDE (chipKIT) users, you need to copy the AccelStepper folder

into both the libraries folder at the top level as well as

\hardware\pic32\libraries so that both the AVR and PIC32 sides can

use it.

Using the same hardware from Example 1, restart the IDE, and enter

the following sketch:

#include <AccelStepper.h>

// Define a stepper and the pins it will use

AccelStepper stepper(AccelStepper::DRIVER, 9, 8);

int pos = 3600;

void setup()

{

stepper.setMaxSpeed(3000);

stepper.setAcceleration(1000);

}

void loop()

{

if (stepper.distanceToGo() == 0)

{

delay(500);

pos = -pos;

stepper.moveTo(pos);\

}

stepper.run();

}

This code does basically the same thing as Example 2, but

using acceleration/deceleration via the AccelStepper library, and

running for twice as many steps. (Thanks Mr. Duffy for pointing out

this important fact!) The reason it runs twice as many steps is

because we do "pos = -pos" to keep things short and simple. This

means that it will run from 0 to 3600, then from 3600 to -3600

(which is 7200 steps).

Example 4: Running multiple stepper motors

One of the great things about the AccelStepper library is that you

can run as many stepper motors as you want, at the same time, just

by making more AccelStepper objects. Now, if you try to run them too

fast, the steps won't be smooth, so you have to be careful not to

load down the Arduino too much. The chipKIT does not have this

problem because it is so much faster than the Arduino.

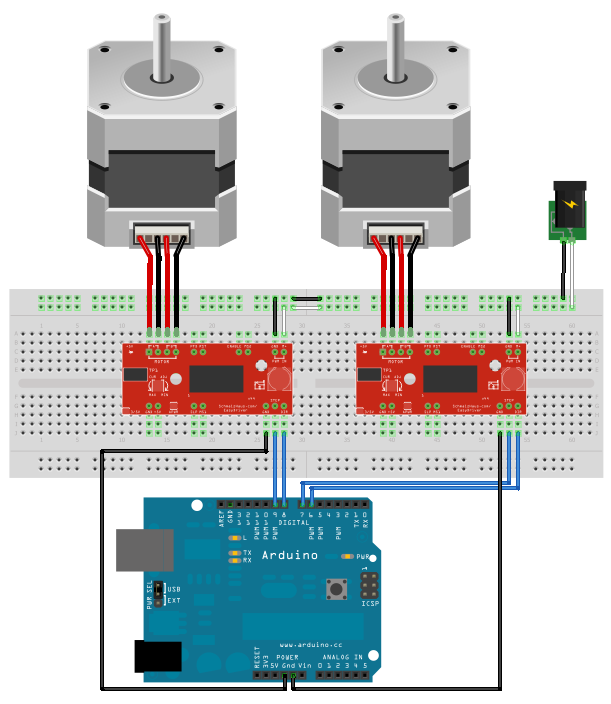

In this diagram, we now have two Easy Drivers and two stepper

motors. We just need 2 more pins from the Arduino to add this second

motor.

The code for this example is shown

below:

#include <AccelStepper.h>

// Define two steppers and the pins they will use

AccelStepper stepper1(AccelStepper::DRIVER, 9, 8);

AccelStepper stepper2(AccelStepper::DRIVER, 7, 6);

int pos1 = 3600;

int pos2 = 5678;

void setup()

{

stepper1.setMaxSpeed(3000);

stepper1.setAcceleration(1000);

stepper2.setMaxSpeed(2000);

stepper2.setAcceleration(800);

}

void loop()

{

if (stepper1.distanceToGo() == 0)

{

pos1 = -pos1;

stepper1.moveTo(pos1);

}

if (stepper2.distanceToGo() == 0)

{

pos2 = -pos2;

stepper2.moveTo(pos2);

}

stepper1.run();

stepper2.run();

}

You can see that for this example, I just copied and pasted the code

from Example 3 and made two positions and two steppers. This example

code is very simple and not all that useful, but you can study the

existing examples from the AccelStepper library, and read the help

pages on the different functions, and get good ideas about what else

you can do with your stepper control.

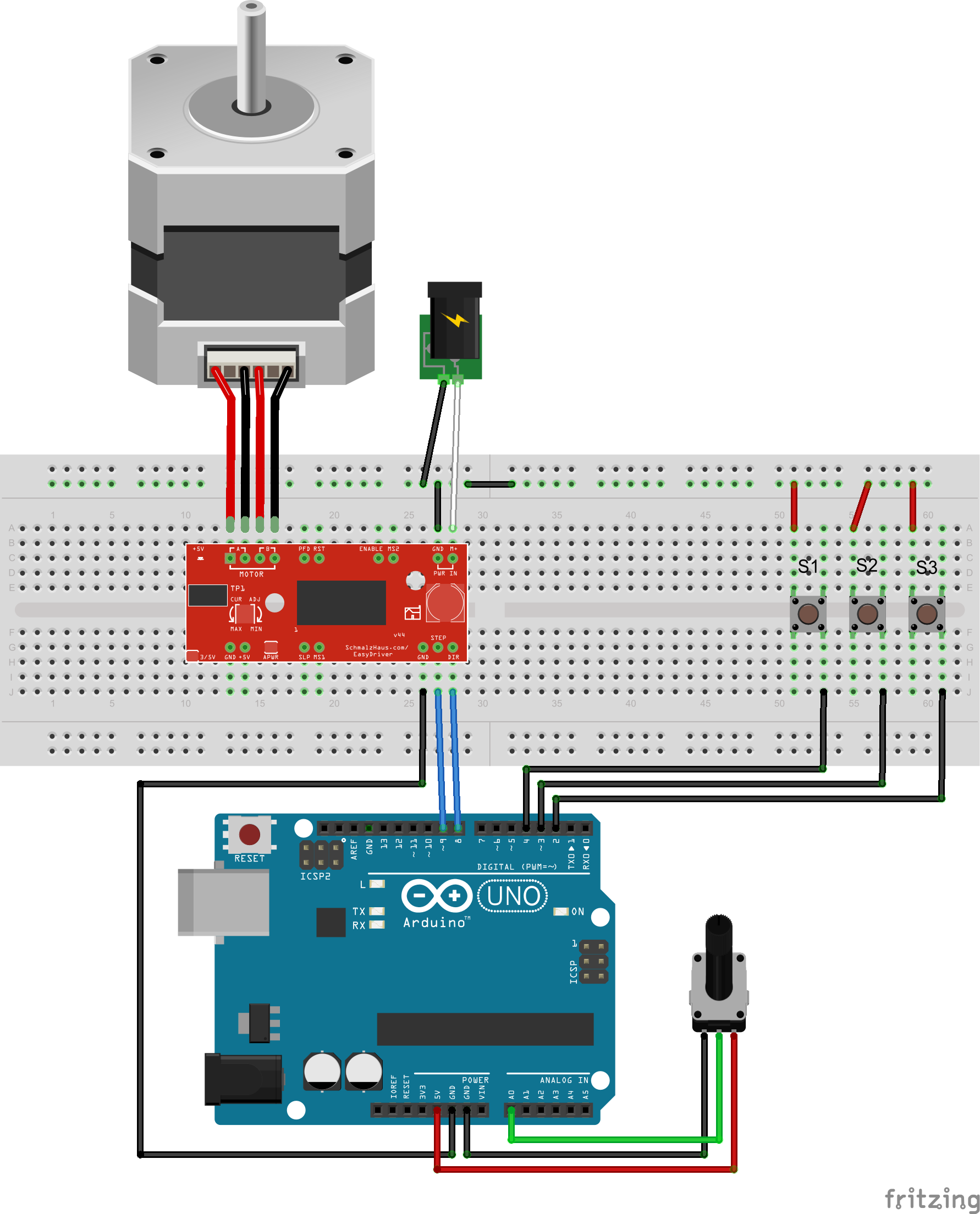

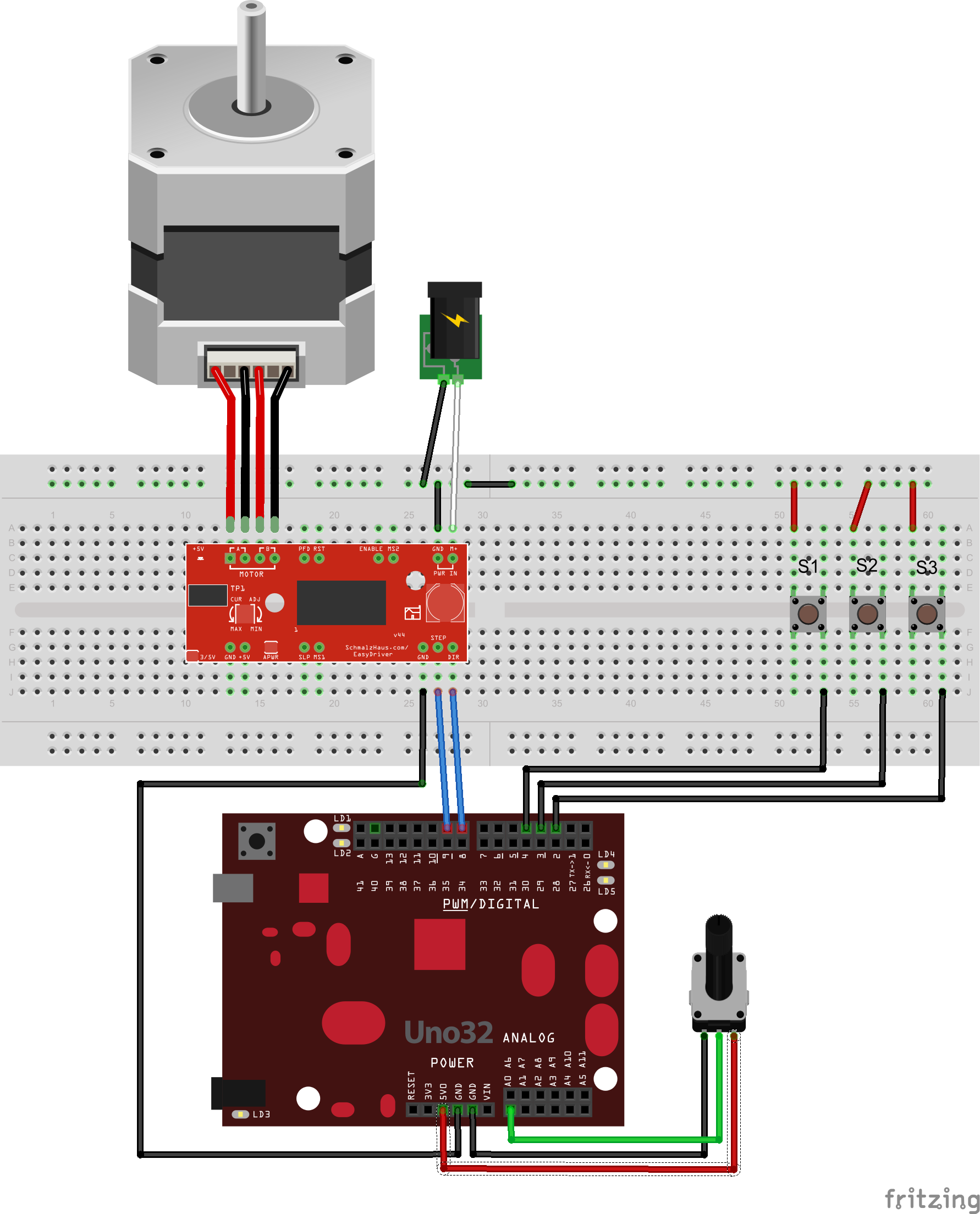

Example 5: Changing motor speed

Sometimes you need to have real time control of the speed of the

stepper motor. Say, for example, you're making a mount for your

telescope. You get a really nice geared stepper motor, you get a Big

Easy Driver with 16x microstepping, and you connect them all up. But

how do you control the speed of the stepper so that it matches the

speed of the stars across the sky?

One easy way is to use a potentiometer, which produces an analog

voltage output that you can control. The sketch code can read this

analog value using the analogRead() command. Then we can use that

value to change how fast we move the motor.

Here's a simple example of this concept. We've added a pot and three

push buttons to our single stepper motor circuit. Pushing switch S1

will cause the motor to turn in one direction, S3 will cause it to

turn in the other direction, and S2 will stop the motor. You can

then use the pot to adjust the exact speed of the motor while

stepping. You may want to adjust the MAX_SPEED and MIN_SPEED values

in the code for you application - depending on your particular

setup, you may want the pot's speed range to be different from what

we've written here.

Just to show how similar these circuits look, we've also included a

version of the diagram with a chipKIT Uno32 board. (Any Arduino or

chipKIT board will work for any of these examples, of course. The

Uno and Uno32 are just easy to diagram.)

The code for this example is shown

below:

// Example5 code for Brian

Schmalz's Easy Driver Example page

//

http://www.schmalzhaus.com/EasyDriver/EasyDriverExamples.html

#include <AccelStepper.h>

// Define the stepper and the pins it will use

AccelStepper stepper1(AccelStepper::DRIVER, 9, 8);

// Define our three input button pins

#define LEFT_PIN 4

#define STOP_PIN 3

#define RIGHT_PIN 2

// Define our analog pot input pin

#define SPEED_PIN 0

// Define our maximum and minimum speed in steps

per second (scale pot to these)

#define MAX_SPEED 500

#define MIN_SPEED 0.1

void setup() {

// The only AccelStepper value we have to

set here is the max speeed, which is higher than we'll ever go

stepper1.setMaxSpeed(10000.0);

// Set up the three button inputs, with

pullups

pinMode(LEFT_PIN, INPUT_PULLUP);

pinMode(STOP_PIN, INPUT_PULLUP);

pinMode(RIGHT_PIN, INPUT_PULLUP);

}

void loop() {

static float current_speed =

0.0; // Holds

current motor speed in steps/second

static int analog_read_counter =

1000; // Counts down to 0 to fire analog

read

static char sign =

0;

// Holds -1, 1 or 0 to turn the motor on/off and control

direction

static int analog_value =

0;

// Holds raw analog value.

// If a switch is pushed down (low), set the

sign value appropriately

if (digitalRead(LEFT_PIN) == 0) {

sign = 1;

}

else if (digitalRead(RIGHT_PIN) == 0)

{

sign = -1;

}

else if (digitalRead(STOP_PIN) == 0) {

sign = 0;

}

// We only want to read the pot every so

often (because it takes a long time we don't

// want to do it every time through the main

loop).

if (analog_read_counter > 0) {

analog_read_counter--;

}

else {

analog_read_counter = 3000;

// Now read the pot (from 0 to

1023)

analog_value =

analogRead(SPEED_PIN);

// Give the stepper a chance to

step if it needs to

stepper1.runSpeed();

// And scale the pot's

value from min to max speeds

current_speed = sign *

(((analog_value/1023.0) * (MAX_SPEED - MIN_SPEED)) +

MIN_SPEED);

// Update the stepper to run at

this new speed

stepper1.setSpeed(current_speed);

}

// This will run the stepper at a constant

speed

stepper1.runSpeed();

}

Some explanation on this example code: Because reading the analog

value takes a (relatively) long period of time, and during that time

we can't be updating the stepper motor's position (that only happens

in the runSpeed() call) we only grab a new analog value every 3000

times through the main loop. We do this by using a counter called

analog_read_counter, and decrementing it each time through the loop

until it gets to zero. Then we reload it with 3000, and perform the

analog conversion.

We've also inserted a runSpeed() call between the analog conversion

and the math necessary to scale the result to MAX_SPEED and

MIN_SPEED. This is because that math also takes a (relatively) long

time, and so we want to give the stepper a chance to step (if it

needs to) in between these to time intensive operations.

You can adjust the values of MIN_SPEED and MAX_SPEED to make the

range of speeds whatever you want. Note that there are only 1024

possible values that the analogRead() call can return, and so there

are only that many discrete speeds the motor can take on.

For this example (because we wanted it to be just a fixed speed) we

did not use the normal AccelStepper run() call, but rather the

runSpeed() call.

Example 6: Changing motor speed -

With an Adafruit Motor Shield (v1)

This example does exactly the same thing as Example 5, but instead

of using an Easy Driver or Big Easy Driver it uses an Adafruit Motor

Shield. This first sketch is for the v1.2 shield, and the next

sketch (see below) is for the v2 shield.

Also note that because the v1 AFMotorShield uses up almost all of

the digital I/O pins, we had to move the three buttons over to the

analog inputs. This is fine because you can always use analog input

pins as digital inputs as well. We are also not using any

microstepping in this example, so our motor has 200 steps/rev.

And of course, Fritzing doesn't have the Adafruit Motor Shield, so I

can't easily create a drawing for you. But it's very simple - the

stepper motor goes into the M1 and M2 terminals on the Motor Shield,

you put your motor power into the M+ and GND terminals on the motor

shield, take the three switch wires and connect them to A5, A4 and

A3, the center tap of the pot goes to A0, and then just tie the

other side of all of the switches to GND and the top and bottom of

the pot to +5 and GND, and you're all set. I tested this code with

an Arduino Uno. (I tried with an UNO32 but I couldn't get the analog

inputs to use built-in pullups because I don't think the UNO32 can

do that.)

// Example6 code for Brian Schmalz's Easy Driver Example page

//

http://www.schmalzhaus.com/EasyDriver/EasyDriverExamples.html

#include <AccelStepper.h>

#include <AFMotor.h>

// Define the stepper and the pins it will use

AF_Stepper motor1(200, 1);

// you can change these to DOUBLE or INTERLEAVE or

MICROSTEP!

void forwardstep() {

motor1.onestep(FORWARD, SINGLE);

}

void backwardstep() {

motor1.onestep(BACKWARD, SINGLE);

}

AccelStepper stepper1(forwardstep, backwardstep); // use

functions to step

// Define our three input button pins

#define LEFT_PIN A5

#define STOP_PIN A4

#define RIGHT_PIN A3

// Define our analog pot input pin

#define SPEED_PIN A0

// Define our maximum and minimum speed in steps per second

(scale pot to these)

#define MAX_SPEED 500

#define MIN_SPEED 0.1

void setup() {

// The only AccelStepper value we have to set here

is the max speeed, which is higher than we'll ever go

stepper1.setMaxSpeed(500.0);

// Set up the three button inputs, with pullups

pinMode(LEFT_PIN, INPUT_PULLUP);

pinMode(STOP_PIN, INPUT_PULLUP);

pinMode(RIGHT_PIN, INPUT_PULLUP);

}

void loop() {

static float current_speed =

0.0; // Holds

current motor speed in steps/second

static int analog_read_counter =

1000; // Counts down to 0 to fire analog read

static char sign =

0;

// Holds -1, 1 or 0 to turn the motor on/off and control direction

static int analog_value =

0;

// Holds raw analog value.

// If a switch is pushed down (low), set the sign

value appropriately

if (digitalRead(LEFT_PIN) == 0) {

sign = 1;

}

if (digitalRead(RIGHT_PIN) == 0) {

sign = -1;

}

if (digitalRead(STOP_PIN) == 0) {

sign = 0;

}

// We only want to read the pot every so often

(because it takes a long time we don't

// want to do it every time through the main

loop).

if (analog_read_counter > 0) {

analog_read_counter--;

}

else {

analog_read_counter = 3000;

// Now read the pot (from 0 to 1023)

analog_value = analogRead(SPEED_PIN);

// Give the stepper a chance to step if

it needs to

stepper1.runSpeed();

// And scale the pot's value from

min to max speeds

current_speed = sign *

((analog_value/1023.0) * (MAX_SPEED - MIN_SPEED)) + MIN_SPEED;

// Update the stepper to run at this new

speed

stepper1.setSpeed(current_speed);

}

// This will run the stepper at a constant speed

stepper1.runSpeed();

}

And with an Adafruit Motor Shield V2

Note that the Left, Stop and Right inputs are now back on digital

pins 2, 3 and 4 for the V2 shield, as it doesn't need them and so

we can use them again.

// Example6 code for Brian Schmalz's Easy Driver Example page

//

http://www.schmalzhaus.com/EasyDriver/EasyDriverExamples.html

#include <AccelStepper.h>

#include <Wire.h>

#include <Adafruit_MotorShield.h>

// Define the stepper and the pins it will use

Adafruit_MotorShield AFMS = Adafruit_MotorShield();

Adafruit_StepperMotor *motor1 = AFMS.getStepper(200,

1);

// you can change these to DOUBLE or INTERLEAVE or

MICROSTEP!

void forwardstep() {

motor1->onestep(FORWARD, SINGLE);

}

void backwardstep() {

motor1->onestep(BACKWARD, SINGLE);

}

AccelStepper stepper1(forwardstep, backwardstep); //

use functions to step

// Define our three input button pins

#define LEFT_PIN 2

#define STOP_PIN 3

#define RIGHT_PIN 4

// Define our analog pot input pin

#define SPEED_PIN A0

// Define our maximum and minimum speed in steps per

second (scale pot to these)

#define MAX_SPEED 500

#define MIN_SPEED 0.1

void setup() {

AFMS.begin();

// The only AccelStepper value we have to set

here is the max speed, which is higher than we'll ever go

stepper1.setMaxSpeed(500.0);

// Set up the three button inputs, with pullups

pinMode(LEFT_PIN, INPUT_PULLUP);

pinMode(STOP_PIN, INPUT_PULLUP);

pinMode(RIGHT_PIN, INPUT_PULLUP);

}

void loop() {

static float current_speed =

0.0; // Holds

current motor speed in steps/second

static int analog_read_counter =

1000; // Counts down to 0 to fire analog read

static char sign =

0;

// Holds -1, 1 or 0 to turn the motor on/off and control direction

static int analog_value =

0;

// Holds raw analog value.

// If a switch is pushed down (low), set the

sign value appropriately

if (digitalRead(LEFT_PIN) == 0) {

sign = 1;

}

if (digitalRead(RIGHT_PIN) == 0)

{

sign = -1;

}

if (digitalRead(STOP_PIN) == 0) {

sign = 0;

}

// We only want to read the pot every so often

(because it takes a long time we don't

// want to do it every time through the main

loop).

if (analog_read_counter > 0) {

analog_read_counter--;

}

else {

analog_read_counter = 3000;

// Now read the pot (from 0 to 1023)

analog_value =

analogRead(SPEED_PIN);

// Give the stepper a chance to step

if it needs to

stepper1.runSpeed();

// And scale the pot's value

from min to max speeds

current_speed = sign *

((analog_value/1023.0) * (MAX_SPEED - MIN_SPEED)) + MIN_SPEED;

// Update the stepper to run at this

new speed

stepper1.setSpeed(current_speed);

}

// This will run the stepper at a constant speed

stepper1.runSpeed();

}

Example 7: Serial command input

Using the exact same hardware setup as Example 1, this sketch

illustrates how to use simple one letter commands from the serial

port to control the direction and speed of the stepper motor.

// Example7 for Brian Schmalz's Easy Driver Example page

//

http://www.schmalzhaus.com/EasyDriver/EasyDriverExamples.html

// We control the direction and speed of a stepper using

the

// arduino serial port. Note that (if using the Serial

Monitor)

// you will need to press Enter after each command.

#include <AccelStepper.h>

AccelStepper stepper(AccelStepper::DRIVER, 9, 8);

int spd = 1000; // The current speed in

steps/second

int sign = 1; // Either 1, 0

or -1

void setup()

{

Serial.begin(9600);

stepper.setMaxSpeed(1000);

stepper.setSpeed(1000);

}

void loop()

{

char c;

if(Serial.available()) {

c = Serial.read();

if (c == 'f') { // forward

sign = 1;

}

if (c == 'r') { // reverse

sign = -1;

}

if (c == 's') { // stop

sign = 0;

}

if (c == '1') { // super slow

spd = 10;

}

if (c == '2') { // medium

spd = 100;

}

if (c == '3') { // fast

spd = 1000;

}

stepper.setSpeed(sign * spd);

}

stepper.runSpeed();

}

Using stepper motors with RC servo inputs

This

page describes a one channel system (running on a chipKIT

Fubarino Mini, with a Big Easy Driver) that reads RC servo channel

information from a receiver and spins a stepper motor accordingly.

This

page describes a two channel version.

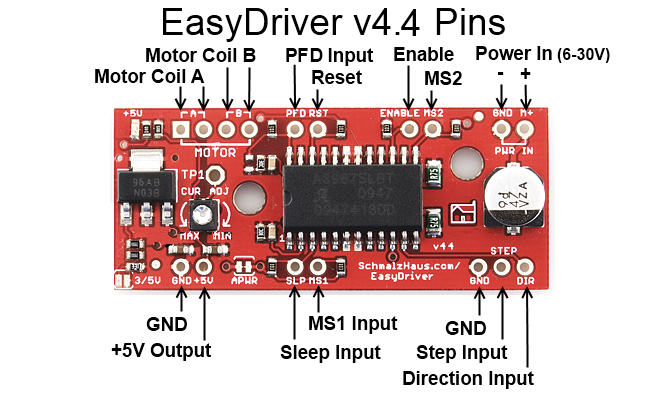

References:

Easy Driver Pinout:

Questions? E-mail me at